Overhaul and reform

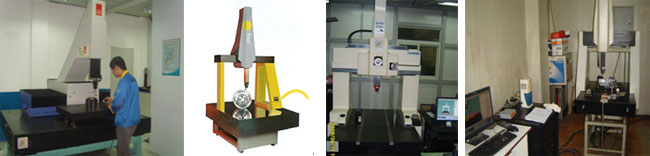

【Overhaul and reform of measuring machine】The overhaul and reform of the measuring machine refer to comprehensive inspection and repair upon measuring machine on the basis of existing situation, upgrade and reform some parts of measuring machine in an economic way so as to realize enhancement on stability, maintenance, measuring capacity, function as well as measuring efficiency.

【Control system upgrade】

By upgrading and reforming the control system, measuring system and transmission system in full, a set of old measuring machines with superior guideway and stable mechanical system can be renewed to extend its service life, enhance the advanced technology and meanwhile reduce service expenses and risks further.

This is the most economic method to renew a used measuring machine. Less than 50% of a new machine’s price can cover the replacement of controlling system, computer system, and measuring software system, overhaul of mechanical part, replacement of totally aging windpipe and air passage, all controlling cable and even upgrade or replacement of probe system.

Our upgrade and reform experts have profound technology basis, rich experiences in reforming measuring machine. They will introduce and recommend the controlling system and its upgrade plan appropriate to you subject to your actual demands.

【Upgrade and reform of probe】

In industrial measurement, scan usually has connection with surface of free shape and complicated geometric body, which is an effective way to rapidly obtain a large quantity of data points. Making use of these points, we can describe the geometric characteristics more precisely.

Data density, confidence level and uncertainty are interrelated. With the increase of data points, the uncertainty will decrease. Because of fitting relation, the shape error of box type parts is crucial. Therefore, the measurement and control of the shape need to collect the data points with a high intensity. The box type parts will be benefited in scanning.

According to measuring requirements of users, we apply Renishaw series of probe and laser probe in the current measuring system. Using probe system, the current measuring system can be upgraded to be high precision scanning system without replacement of controlling system and software, or upgrade the previous manual probe to be automatic revolving probe system. The upgraded measuring system will fully satisfy the measuring demand on high precision, high efficiency and high performance.

▼ Measurement of holes:

High speed scanning means obtaining a mass of data points within several seconds, which makes it possible that the characteristics of holes can be completely described (such as dimension, position and shape) and ensure high precision and repeatability. Additionally, plug gage and ring gage can be simulated. These provide reliable calculation on large diameter workpiece appropriate to the hole.

▼ Measurement of column:

Through collecting many data point on each measured section, the shape and axis of column can be definite more precisely and evaluate key characteristics of dimension and shape, such as maximum and minimum characteristic dimension, to support the fitting analysis of workpiece.

▼ Measurement of plane:

The scanning can provide many more data points for evaluating shape error and arranging workpiece and spend less time than traditional point-to-point method. The result is to enhance the precision of assembly, which can be indicated by that the overall measuring precision.

- PREV:External service

- NEXT:Redevelopment

Address:U Valley, Liandong, 328 Chengkang Road, Chengyang District, Qingdao, China. Postcode:266100

Telephone:+86-0532-87602111 E-mail: info@metro-3d.com 鲁ICP备14028182号-2